As India positions itself at the forefront of clean and connected mobility, engineering simulation has become a crucial enabler of innovation. At the heart of this shift is CADFEM APAC, a key simulation partner across India and Southeast Asia. As part of the global CADFEM Group—founded in 1985 in Germany—CADFEM has built a legacy over the past 40 years of driving simulation-led transformation across industries, including automotive, aerospace, semiconductors, electronics, and more.

Today, it stands as one of the largest Ansys Elite Channel Partners globally, providing end-to-end simulation solutions that help companies bring better, safer, and smarter products to market faster.

Transforming Development Through Simulation

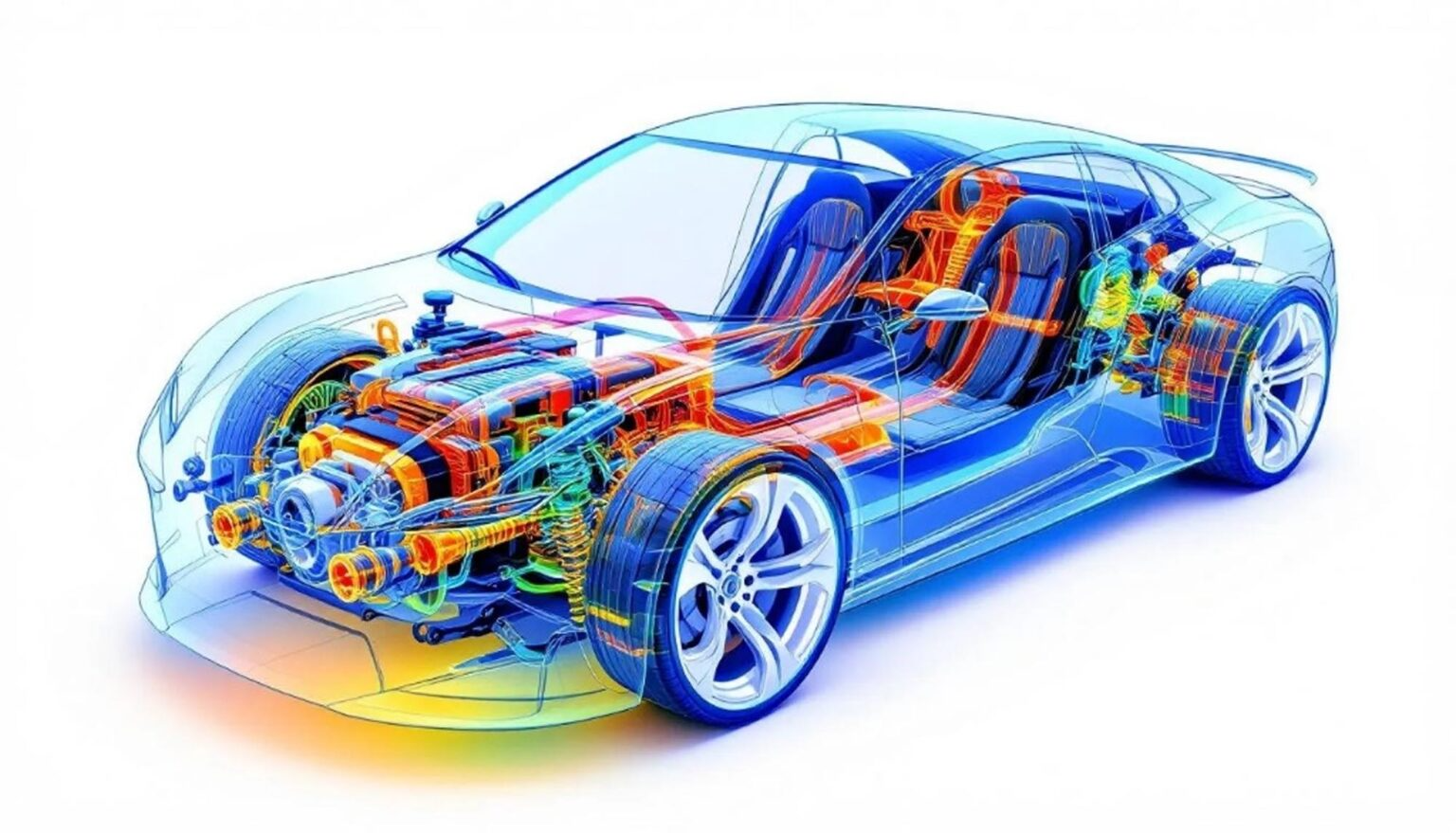

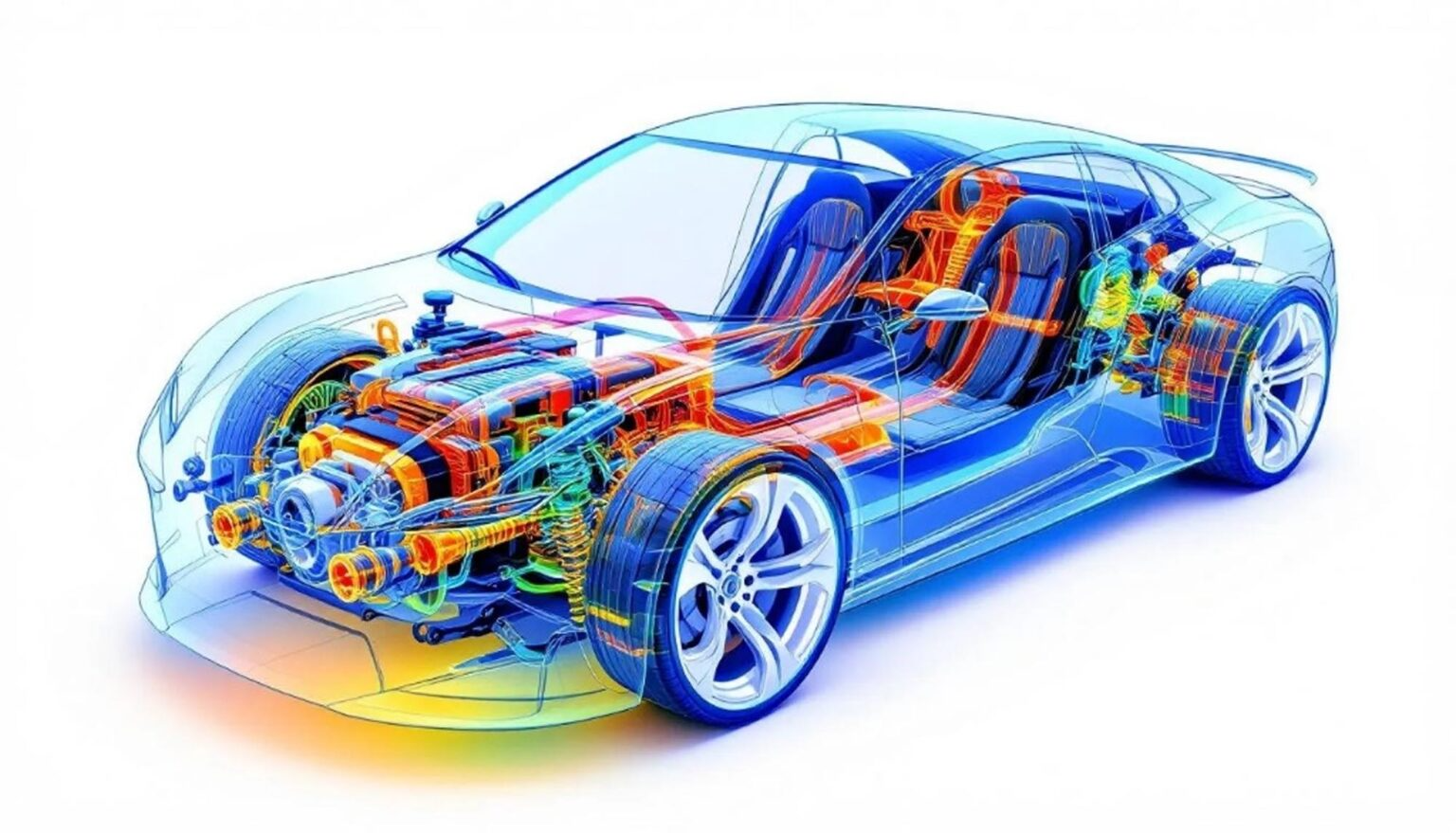

Simulation is radically improving how Indian automotive and EV manufacturers design, validate, and launch products. From battery modelling and e-motor design to crash testing, thermal management, and EMI/EMC compliance, virtual testing enables early-stage decisions that reduce errors, costs, and timelines. It also helps companies meet global standards such as ISO 26262 for functional safety and ISO 21434 for cybersecurity.

CADFEM has supported numerous startups and OEMs in deploying Ansys tools for co-simulation of thermal and electromagnetic behaviour—leading to development cycles being reduced by over six months in some cases. This shift from physical iteration to virtual prototyping is streamlining innovation across the value chain.

Enabling Advanced Powertrains and Battery Systems

With electric mobility accelerating rapidly, the demand for robust, efficient, and reliable EV powertrains is at an all-time high. CADFEM helps OEMs and Tier-1s virtually design and validate motor systems, converters, and battery packs using Ansys tools like HFSS, SIwave, Icepak, Maxwell, Fluent, and Mechanical, while incorporating Medini Analyze to ensure safety and architecture-level traceability.

An excellent example is Nhanz Systems, which developed a compact, high-efficiency 3.6 kW onboard charger with over 93% efficiency and 20% lower BOM cost using SIwave and Icepak. Simulation enabled them to achieve performance, compliance, and manufacturability—without waiting for physical builds.

Balancing Compliance, Quality, and Time-to-Market

Manufacturers are increasingly tasked with meeting global safety, cybersecurity, and emissions regulations while competing in fast-moving markets. CADFEM provides simulation-led workflows that cover crash simulations, emissions modelling, NVH, structural fatigue, and electromagnetic interference.

Tools like LS-DYNA, Sherlock, Mechanical, and Fluent are used to build robust digital twins that allow for comprehensive virtual testing long before production begins. As EV architectures grow in complexity, Ansys Medini Analyze adds value by offering model-based support for both functional safety and cybersecurity—ensuring system reliability and standards compliance without compromising innovation.

Reducing Cost and Supporting Localization

Cost sensitivity and localization are key in India’s EV development. Simulation helps manufacturers reduce reliance on physical prototyping while improving quality and system-level performance. CADFEM works closely with local manufacturers—particularly in the two- and three-wheeler markets—to optimize packaging, thermal design, PCB reliability, and EMC, all within real-world constraints.

By integrating tools like Sherlock, teams can analyze and predict how design decisions impact durability, lifecycle cost, and manufacturability—leading to better trade-offs early in the development process. This is particularly vital for startups looking to scale fast with minimal capital investment.

Advancing ADAS, SDV, and Electronics Architecture

CADFEM is playing a crucial role in helping Indian automotive players transition to software-defined vehicles (SDVs) and advanced driver-assistance systems (ADAS). With simulation tools such as Ansys AVxcelerate, manufacturers can validate multi-scenario environments with 97–99% accuracy. Meanwhile, Ansys SCADE supports automatic embedded code generation, meeting ISO 26262 ASIL D requirements.

These developments begin with Ansys Medini Analyze, which lays the foundation for safety and cybersecurity architecture across electronic and mechanical domains. The entire electronics design cycle—from RF and signal integrity to thermal performance and compliance—is seamlessly managed through simulation.

Tailored Simulation Across India’s Vehicle Segments

India’s vehicle market is highly diverse, ranging from electric scooters to heavy-duty trucks, and each segment has unique design challenges. CADFEM tailors its simulation approach accordingly.

For two- and three-wheelers, the focus is on compact battery design, charger optimization, and tight electronic packaging. Passenger vehicles benefit from complete crash and thermal simulations, NVH optimization, and autonomous system development, while also ensuring embedded software is both functional and secure. In commercial vehicles and buses, solutions support structural durability, fatigue life analysis using Ansys nCode DesignLife, and thermal management strategies for heavy-load applications.

Shaping the Future of Electric Mobility in India

Looking ahead, CADFEM is committed to advancing India’s mobility ecosystem through strategic partnerships with OEMs, startups, and research institutes. Key focus areas include EV platforms, infrastructure, ADAS, and fleet-level digital twin applications.

Over the next five years, CADFEM aims to become a trusted simulation partner, aligned with digital transformation goals. “Our vision is to establish a digital lab where virtual simulation drives experimentation—enabling sustainable innovation, faster development, and long-term competitive advantage,” says Dr.-Ing. Madhukar Chatiri.

Simulation is no longer optional—it’s essential. And with CADFEM’s expertise, the future of Indian automotive innovation is in powerful hands.